Bridged Physical Damp Poor Course in Matlock

During the property inspection, it was evident that the building followed modern cavity construction, incorporating a physical damp-proof course when originally built. The purpose of a damp-proof course is to prevent damp from rising through the walls, and it is commonly found in buildings constructed around 1900, often using materials like bitumen, slates, lead, pitch, asphalt, or low absorption (Engineering) bricks.

The client contacted us due to signs of dampness at low levels on several internal walls, accompanied by visible crumbling of the plaster along the base of these walls. To investigate the issue, we first inquired about any water leaks or the presence of water pipes in the affected areas, but none were reported. Additionally, drainage problems were ruled out.

To gain insights into the dampness, we employed an electronic moisture meter (Protimeter Surveymaster 2) to create a moisture profile by taking readings at regular intervals vertically up the identified damp walls. While the meter provided qualitative readings for masonry (Wood Moisture Equivalent WME%), it offered quantitative readings for timber (Wood Moisture Content WMC%). However, it is essential to remember that diagnosis should not be solely based on these readings, but rather, a skilled surveyor should interpret the readings alongside visual observations and other evidence.

Our moisture profiling revealed elevated readings along the base of the walls, reaching up to approximately 250mm in height, as well as high moisture content in the skirting boards. Based on this profile and the moisture content in the skirting boards, we suspected that the issue might be related to a floor/wall junction problem or a bridged damp-proof course.

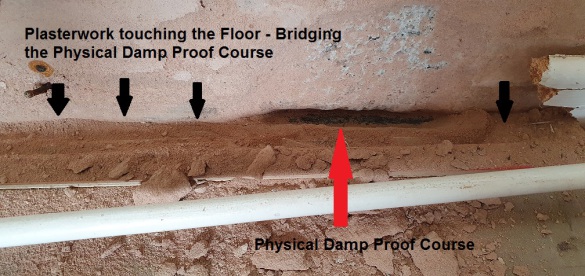

To delve deeper into the matter, we sought permission from the client to remove the skirting boards. This allowed us to discover that the plasterwork on the walls had been taken down to floor level and finished slightly below the finished floor screed. Subsequently, we exposed the original physical damp-proof course, positioned at the very base of the wall.

In summary, the survey indicated the likelihood of a compromised damp-proof course or bridging, enabling moisture to rise from the ground and affect the lower parts of the walls and skirting boards. Further examination by an experienced surveyor is necessary to confirm the diagnosis and recommend appropriate remedial measures to address the dampness effectively.

Further Investigation – Destructive Testing (“Speedy” Carbide Meter)

Determining if the damp proof course is 100% effective is difficult as without x-ray vision, the whole of the physical damp proof course cannot be seen through the entirety of the wall.

We decided that one way we could check as to whether the damp proof course has been protecting the blockwork was to carry out some sampling to the wall just above the position of the damp proof course.

In order to do this, we used a "Speedy" Carbide meter. Carbide meters are one method of measuring moisture content (Total Moisture Content TMC).

This technique works by testing a weighed sample of drilled masonry that has been taken from a sample area such as a mortar joint located above the damp proof course. The sample is then placed in a container. A measured amount of calcium carbide powder is placed in a separate portion of the container, and then the container is sealed. The container is shaken, and the two substances mix together to trigger a reaction that produces acetylene gas if moisture is present. The meter will indicate the results of the test on a pressure gauge.

In the case of the property inspected, the results of the test showed a very low moisture content in the masonry (less than 5%). This suggested that the damp proof course was working and that the only issue had been the low levels of dampness rising up the plasterwork due to the bridged damp proof course/floor wall junction issue.

Conclusion

In conclusion, as suspected, the physical damp proof course was being bridged by the wall plaster and floor screed (Floor/wall junction issue - bridged damp proof course). This allowed for moisture from the edge of the floor to rise up the plasterwork and bypass the damp proof course. Over a long period of time, this caused the plasterwork to crumble. The investigation confirmed our initial suspicion that the bridging issue resulted in localized dampness in the lower part of the walls and the skirting boards. However, the "Speedy" Carbide meter testing, which involved sampling the masonry just above the damp-proof course, showed a very low moisture content (less than 5%), indicating that the damp-proof course itself was functioning effectively in preventing excessive moisture infiltration. To address this problem and prevent further damage, appropriate measures should be taken to restore the damp-proof course's integrity and eliminate the bridging, allowing the building to maintain proper protection against rising damp.